The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Whole of House

- >

- Wood stained internal stairs need spruce...

Wood stained internal stairs need spruced up to hide water stains

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Wood stained internal stairs need spruced up to hide water stains

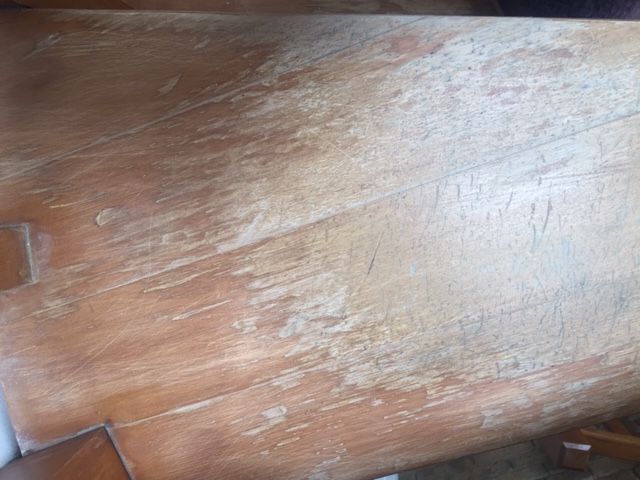

1980's wooden stained spiral stairs need re-furbishing to cover water stains and scratches. At present a very well worn walnut colour - any suggestions as to whether i use a stain or a paint? I really don't want to sand down, I want to patch up but don't want to do all the steps in the stairs, just the worst ones. There are both water stains and etching in the wood from what looks like high heels or steel caps on boots have made the etchings. thanks. Jillie

Solved! See most helpful response

- Labels:

-

Flooring

-

Painting

-

Renovation

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: wood stained internal stairs need spruced up to hide water stains

Hi @Jillie1,

You might be able to disguise the wear marks to an extent with a stain. However, the stairs would benefit from being sanded back with the remaining coating removed to achieve a consistent result. Your stain will penetrate the raw timber where the stairs are worn but won't where the coating is still applied. This could lead to a difference in colouring.

I think you'll find your stairs have a coating on them and not just a stain and I would suggest a product similar to Cabot's Cabothane Clear CFP Floor Polyurethane for this purpose. Whether you use the CFP or a stain I would advise doing a test section to see how well they disguise the worn areas.

I would encourage you to sand the stairs before applying a coating, but I understand this amount of work is not always feasible. You can do a test section with the CFP to see how well it will adhere to the existing coating. Once the test section has dried apply some painters tape to it. Rip the painter tape back up, if it removes the CFP from the surface then more preparation work is needed.

Here's a couple of previous discussions on rejuvenating timber floors: old floor boards refresher by @mpb2011 and Lounge and hallway floorboard sand and seal by @hermes.

You should also find these step-by-step tutorials helpful: How to sand timber floors and How to seal a timber floor.

Let me mention a few helpful members @JDE, @Poppop, @r23on, @woodenwookie who might like to join the conversation.

Please let me know if you need further assistance or had any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Wood stained internal stairs need spruced up to hide water stains

from where I sit the steps look like they have a sealer on then and as suggested by Mitchell a good sanding is required before staining/sealing. I would not be looking to sand the heavy scratching out. I would look to fill the marks with a filler called timber mate mixed into a past and painted on light sanding to finish. the timber mate natural will take on the colour of the stain as it is a water based filler toped off with a hard wearing poly. If you decide to sand, make sure you follow the grain as the cross grain sanding will show up once the stain is applied.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Wood stained internal stairs need spruced up to hide water stains

Hi Mitchell, I've started sanding down, by hand, but its still showing large colour differences between the water stained area and the undamaged area. Am I not sanding the undamaged area enough? I'm concerned too that if I buy the Cabots Cabothane Clear, that it will only emphasis the difference between the areas and also, because i don't want to do all the stairs (too big a job for me and only the top three are really bad) won't I then have three much lighter stairs compared to the rest. Why wouldn't I use a stain/varnish that disguises the differences rather than a 'clear' product. I've looked up the Cabot wood stain colour chart for example, and tried to match the colour on the landing without much luck. Is it a 'stain and varnish' product i want? I've attached images of the landing and of my effort at sanding. Any help would be appreciated. It's quite a red finish: red cedar? merbau? many thks, jill

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Wood stained internal stairs need spruced up to hide water stains

Hi @Jillie1,

Removing the existing coating is not really a hand sanding job as that would be incredibly hard work. The lighter area in the middle is the natural timber colour. It is where the hard coating and stain have been worn away by foot traffic over the years back to the bare timber. I'm not seeing any visible watermarks.

The Cabots Cabothane Clear is a product to use if you sand back the staircase to bare timber restoring it. This is a clear coating with no colourant added to it. If you apply it over what you have now it will not disguise the difference in colouring. You are correct that if you sand three stairs and apply this product it will be much lighter than the bottom stairs and the floor. This is a product that would be used on a full restoration of the whole staircase and if you wished to match the floor you would need to stain first before applying it. I apologise if I wasn't clear that all stairs would need to be sanded.

There are no stain and varnish combinations that I am aware of for floors as they are not hard-wearing products. The products we have available with a stain pre-mixed are for non-trafficked areas like cabinets. You would need to stain first with a Cabot's Oil Based Stain And Varnish and then coat over it with Cabot's 4L Gloss Cabothane Clear CFP Floor Polyurethane.

If you wish to try and disguise the wear with stain the Feast Watson Prooftint range might have some suitable colours available. These tints can be reduced with Feast Watson 250ml Prooftint Colour Reducer to achieve a multitude of lighter shades. Here's their online colour chart to see the options. It is normally quite hard to pick a colour to match when staining timber. You might need to try a couple of different colours in an inconspicuous area to match it correctly.

Please let me know if you have further questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Wood stained internal stairs need spruced up to hide water stains

You have a task ahead of you if you are doing the job by hand. I suggest you get a hold of an orbital sander starting with a course grain sanding material and working your way down down to 240 grit. The timber will then look all the same after sanding. to reduce the number of sanding pads you use you can recycle the pads by washing the pad with simple green which Bunnings has. use the following method.

buy simple green consternate mix a suitable amount to get in under the material stuck on the pad.

Spray the pad let set for about two mins

use a solid brush the imbedded material will come off and let dry and re use again.

I use this method on heavy industrial belts with great success plus on my own sanding equipment.

Most important when using an orbital sander don't press hard on the sander to remove the coating. This only increase the heat factor and causes the sanding pad to clog faster. let the sander do the work. The same applies to hand sanding

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.