The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- How to build a low-level deck?

How to build a low-level deck?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to build a low-level deck?

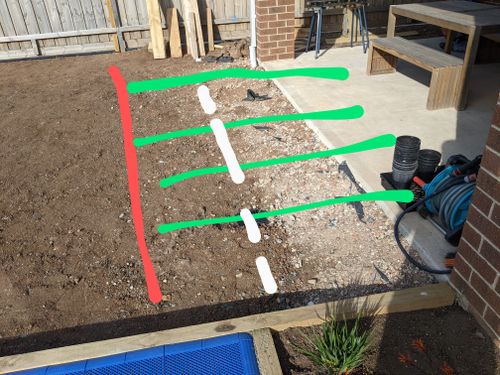

I have an alfresco area which I'd like to deck. The joists (Green lines) will most probably fix straight into the concrete and ideally, I'd like to go 1500mm beyond the concrete (Red line). I have a storm water pipe (White line) about 800mm out from the concrete. 800mm out from the concrete, the ground is at its lowest point, which is about 200mm lower than the alfresco. With regards to the footings and bearers, what are my options?

Community manager's note: Check out How to build a low-level deck for expert advice.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Deck options

Is flashing the joists or bearers using Protectadeck needed?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Deck options

Using Protectadeck is a fantastic way to prevent water pooling on top of your joists and bearers @IronStan001. It will certainly help prevent the early onset of decay and I'd recommend you consider using it. In answer to your question, though, it is not needed and many of our members have built decks successfully without it. Time will tell whether or not using a product like this would have been beneficial to the lifespan of the deck.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Deck options

Agree. I had a deck around 15 years ago at a former house which we didn't use flashing and the deck is still going strong.

Next up, the first joist which is up against the brick wall. What is the best way to fix this considering it's proximity to the wall? Do I:

- Position the joist 10, 20, 30mm (or whatever) away from the wall and set the angle bracket in place with a dynabolt.

- Get my levels right and drill a hole as needed.

- Remove the angle bracket to allow the bolt to be inserted from the wall side

- Fix the backet back to the slab, and the joist to the bracket

Or, fix the joist directly to the brick wall.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Deck options

Hello @IronStan001

I agree with all four suggestions except the last one which is to anchor the joist to the brick wall. I think it will be easier to fix any errors with an angle bracket than it is to fix an error on a brick wall.

I propose leaving a 30mm space between the wall and the joist. It should just be enough space to back off the bolt in order for you to line up the joist to the angle bracket and slot the bolt in.

If your joist levels are correct the drilling marks for your joist should be in line as well.

If you have any other questions we can help with, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Deck options

Great. Plans have been tweaked based on what we've discussed.

90x45mm noggins have been staggered and evenly spaced. The noggins on the ends of every 2nd row may or may not be deleted since it's pretty close to the next noggin.

Joists which are close to the brickwork and where an angle bracket is required, have been moved away by 30mm to allow room for bolts. All other joists will be at least 10mm away from the brickwork.

The joists at the end are set back 40mm from the edge of the brickwork, determined by the actual width of the joist hangar. This same 40mm set back applies to the joist on the opposite side of the brick column.

Boards will be 140x19mm at 5mm spacing.

An additional noggin (70x35mm) may be needed under the board that's cut around the downpipe for support.

I've decided to go with a flush fascia, mostly because it closes the gap from the bottom of the boards, to the concrete just nicely.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Deck options

Hi @IronStan001

Please keep us updated with your progress, we look forward to seeing your low-level deck frame take shape.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Deck options

Regarding the first boards, what would be better (considering, 140x19mm boards):

- Cut the first board as needed to go around the brick

Or...

- Rip the first board down to 95mm (assuming a 5mm gap between the boards) and fix it to the brick

If I go with the former, the board that is cut to go around the downpipe should be ok to support with a noggin.

If I go with the latter, all the boards will be pushed back around 45mm. This would mean the possibility of another joist, or fixing something to the brick column to support the board

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Deck options

I'm a fan of ripping a board down to 95mm and then running the 140mm boards @IronStan001. However, whatever appears to be the most simplistic option might be the best solution.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Deck options

Simpler would be the former, but the first board that's cut around the brick might look a little odd, yet, it would make the board around the downpipe easier.

I think a joist either side of the downpipe might be the way to go so I can rip the first board and make it look neat.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Deck options

I'm planning on going shopping for everything I need. To fix the joists to the concrete, I'll be using 40x40x50x5mm brackets (https://www.bunnings.com.au/dunnings-40-x-80-x-40-x-5mm-m12-galvanised-angle-bracket_p1070088) using galvanized screw bolts. However, what's a good length M12 screw to use here? 60, 75, 80, 100mm?

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.