The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Living and Bedroom

- >

- How to add panelling to a square set ope...

How to add panelling to a square set opening?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to add panelling to a square set opening?

Hello BW,

This is another project on Square Set opening with either Timber or metal material.

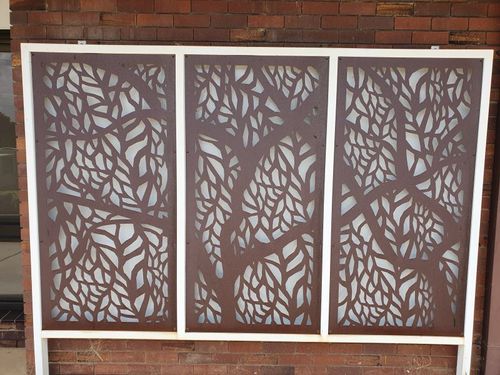

Some of the sample Square Set Opening is provider below, where Timber is used for the design on one photo and metal on another.

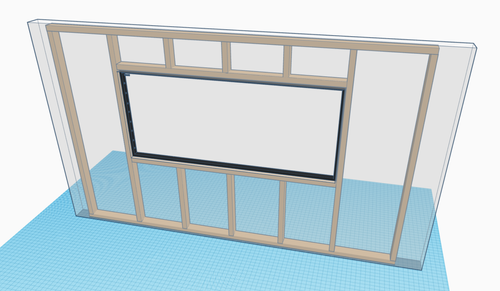

I would like to have any one of the above design in my living room in the space as shown here under.

The questions, I had are (for Timber material)

1. What timber material is fit for the purpose.

2. For painting in in light brown to match with the shelfing, should I remove the shelf door and compare with the paint cards for exact match.

3. How to fix the timber frame, exactly in the square set opening. On above image, I could not find any screws for fixing it in square set opening. Is there a quick fix mechanism available for locking the frame within the opening.

(if it is for steel),

1. Can bunnings assist on laser cut for above design.

2. Does Bunnings sell any design in Steel frame that I can paint and fix in to the opening.

3. How to fix the metal frame in to the square set opening. Is there a quick fix mechanism available for locking the frame within the opening.

Hoping to work on this project with your recommendation and assistance.

Happy Maintaining your space.

Thanks

MM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to add panelling to a square set opening?

Hi @nagumuthu,

That's quite an impressive project you are embarking on.

Here are some answers to your questions:

1. Typically, you used dressed timber to construct something like this. This 42 x 18mm 5.4m Moulding White Pine FJ Primed DAR would be suitable.

2. You could either paint the timber brown or stain it with a suitable colour. If you'd like to see the timber grain, then a stain would be the way to go. Taking the cabinet door into a store with you would be a good way to match up colours.

3. To lock the frame into the opening, you'd pre-drill the side of the frame and then screw through it into the edge of the opening. Directly behind the plaster will be the timber studs, which you'll be screwing into.

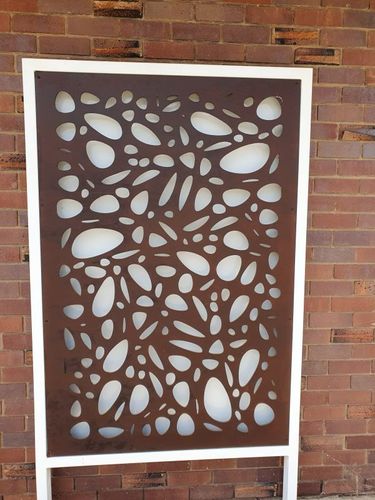

1. We currently do not have the capability to laser-cut panels. However, you might like to check out our range of decorative panels. This 1200 x 2400mm ACP Profile 12 Decorative Panel Unframed is similar to your inspiration image, but there are many more to choose from.

2. The majority of our decorative panels are plastic that can be coated with the correct preparation. We have a limited range of steel panels, but this geometric design is very nice.

3. Once again, the steel frames would need to be fixed with screws into the surrounding opening. There's no real quick-fix option that I can think of.

Let me ask a few of our knowledgeable members @Jewelleryrescue, @diy_hausdesigns and @craftyhopper if they have any thoughts.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Square Set Opening

Morning @nagumuthu

I like the wood one above. Looking closely at it - it appears to be built in sections with multiple panels, which seems doable and more forgiving than steel. I certainly wouldn't be making it 'one piece.' A good mitre saw and we're in business. 😁

I don't get out much - and see inside modern homes - is this 'hole in the wall' concept common?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Square Set Opening

Thanks @MitchellMc for your recommended timber materials. That provides me confidence that it is doable with dedicated effort.

May I know what is meant by 'Stain' (..... If you'd like to see the timber grain, then a stain ...). By the way, should the screws be painted in same color before sloting it in for the match. I did face problems in spray painting (using can), that the paint in the screws sticked to the plastic sheet, where they are placed and sprayed. Is that the right way for spray painting (or) they are to be sprayed after fixing in to the spot.

Can you please brief more on 'surrounding opening' (......fixed with screws into the surrounding opening.....)

Thanks.

MM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Square Set Opening

Hello @Noyade

Thanks for the assurance that it is doable. The tool I hold on to is circular saw (https://www.bunnings.com.au/ozito-pxc-18v-165mm-circular-saw-skin-only_p0033141) and not a Mitre Saw. Hopefully, I can complete the design and not sure whether above cicular saw will be able to do the job.

Hello @MitchellMc

To speed up the process, will Bunnings trim the timber according to different sizes; I remember in one of the thread, it is answered as 'Yes'. Adding on to that, is drilling (Countersunk) at different position in the timber performed at bunnings ?. That allows to quickly screw the wood screws fixing each piece to the frame.

Thanks

MM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Square Set Opening

Hello @MitchellMc

Ths problem with plastic and metal panels are they cant fit exactly in full to the square set opening as their size (in one panel or two panels joined together) does not match. The design looks good. If they are to be cut (plastic or metal screen panel), which tool is to be used.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Square Set Opening

Hello @MitchellMc

@I missed to mention that the tradie who affixed the completed timber is briliant enough that no screws are found in the frame anywhere around the frame. How is it possible without screws? Is that affixed through glue in any way?

Another question is for painting. I reckon it is through brush. The paint sticks to plastic sheet. I have to paint top side and the test (except bottom) and let it dry and the ext day, flip and paint the bottom side ? Is this method or react ?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Square Set Opening

Hi @nagumuthu,

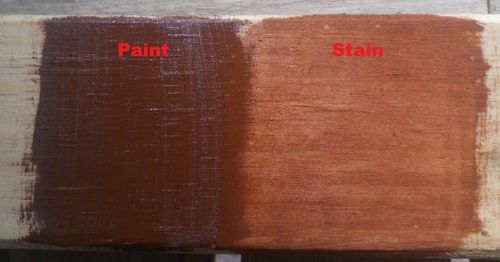

Stain is a transparent dye that changes the colour of the timber. Unlike paint that is opaque and non-transparent, stain allows you to darken timber without covering over it entirely. I've placed some paint and stain next to each other on a piece of timber so you can see the difference. Stains come in many different colours, and the more of it you apply, the darker to colour gets.

You can paint your screws or drive them below the surface of the timber and use filler over the top. You'll need to fill over the screw heads for a truly invisible look. There are coloured screws available, like the Pinnacle 5 x 50mm Black Countersunk Timber Screws. When spray painting my screws, I like to screw them into cardboard or foam so they stand upright. That way, you can spray them and let them dry, and they won't stick to anything.

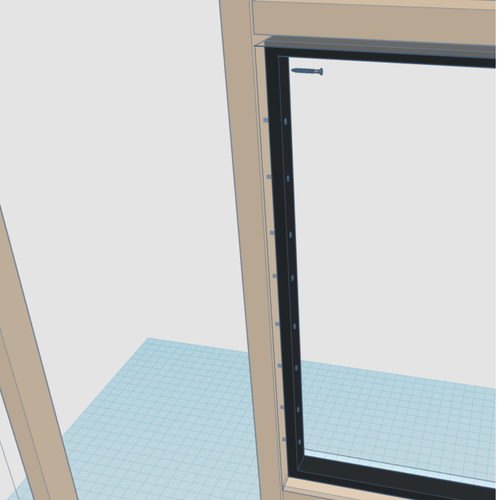

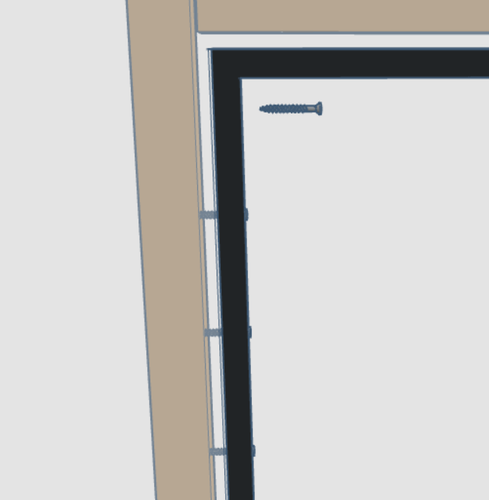

Please see the renderings I've created below for more information on fixing into the surrounding opening. You'll be fixing the frame to the side face of the opening with screws. There will be timberwork behind the plaster that you can screw into.

@Noyade has suggested a mitre saw as it is far superior to a circular saw when cutting the same angle over and over again. It's far more accurate, and you'd struggle to complete this timber project with a circular saw. I know I certainly couldn't complete those cuts with a circular saw with any accuracy.

We can cut timber to length for you, but the team is unable to cut up all the pieces for this project. Our saws do not have the option to perform mitre cuts. We don't offer a counter-drilling service at the store. I'd suggest you pick yourself up a pack of counter-sink bits.

To cut the plastic screen panels, you can either use a jigsaw or an ordinary hand saw. For the steel panels, you'd need to use an angle grinder or tin snips.

The tradesperson has likely countersunk the screw heads beneath the surface of the timber and then filled over them before painting. This will make the screw positions unnoticeable. Glue was probably used as well, but it might not have been the only securing method.

You could use a brush to paint the panels, and doing one side at a time and letting it dry before flipping is a good approach.

I just wanted to point out that creating these geometric patterns all from timber requires some precision cutting and joining. I would consider it an advanced project to make this screen from scratch, and the tradesperson that constructed it likely had many years of practice before getting to this level of finish. I have no doubt that with time and patience, you could achieve similar results, but please understand that it will be a lot of work. That's why I'd encourage you to consider utilising prefabricated screens in your project.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Square Set Opening

Hello @MitchellMc

Thanks for explaining in detail. I will run through it one more time this evening.

A quick one. For pre-fabricated screen ( Plastic)

1. Joining two panels for the square set opening - will it be sturdy.

2. Painting on above plastic panel possible?

3. Securing them with unnoticeable screws possible ?

Thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Square Set Opening

What about a wooden and purchased panel combination? That would reduce the amount of woodwork required.

Spotted some garden based panels on the weekend.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.