The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- How To

- >

- How to install a shed floor

How to install a shed floor

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Intermediate

Installing a floor keeps items dry in your shed and improves insulation.

Turn your shed into a more functional storage space by following this guide to installing a raised floor. You can customise this project according to the size of your shed.

As this project involves power tools, please follow all safety guidelines provided by manufacturers and use the recommended protective gear.

You can also check out our step-by-step guide on How to waterproof a shed floor to make your shed more functional. Let us know if you have any questions.

Steps

Step 1

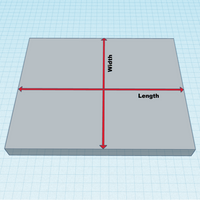

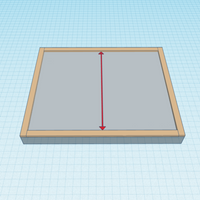

Measure the shed floor.

Clear out any items in your shed. Remove any existing flooring or debris to ensure you have a suitable working surface.

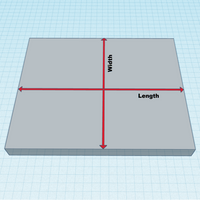

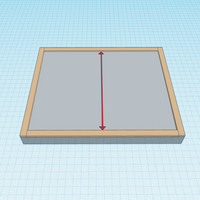

Measure the internal width and length of the shed's foundation between the walls using a tape measure.

Step 2

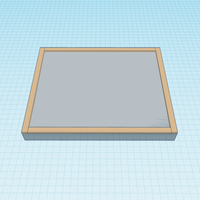

Cut the timber for the floor frame.

Take four pieces of the 90 x 35mm timber.

Mark the width of your shed's floor on two timber pieces. Now mark the length of the floor on the other two pieces after subtracting 180mm. This adjustment will help ensure all your timber pieces fit snugly on your floor.

Cut all four pieces of timber to the appropriate size using a circular saw. Make sure you are wearing the required protective gear before cutting, including gloves and safety glasses.

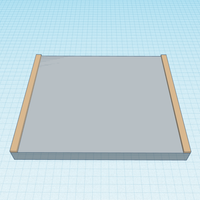

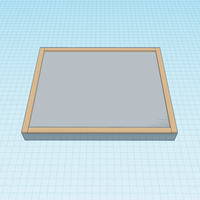

Place the cut timber pieces on the shed floor, positioning them to form a frame.

Step 3

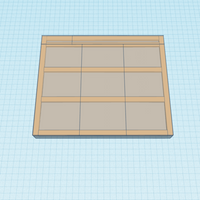

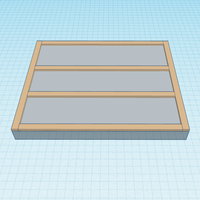

Cut the joists.

Measure the distance between the frame pieces and divide this length by 450mm. This will give you the required number of joists needed for your floor.

Now subtract 180mm from the length of the shed's floor to determine the length of the joists, as in the previous step. Use a circular saw to cut the required number of joists according to this length.

Depending on the width of your shed, you might need to cut an additional length of timber to support the end of the flooring sheets, as they typically measure 1800mm long.

My shed is 1900mm wide, so I added an additional joist at the end.

Step 4

Coat the frame pieces and the joists.

Remove the frame pieces and the joists from the shed and set them up on a work surface.

Apply a waterproofing bitumen rubber coating to the bottom, sides, and ends of all the cut timber. Using a disposable paint roller is an easy way of ensuring thorough coverage.

Allow the coated timber to dry, and if needed, apply a second coat for better protection.

Step 5

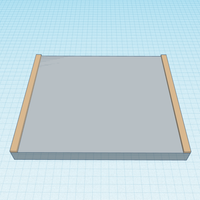

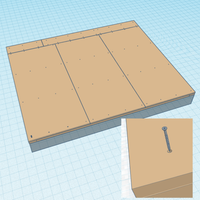

Secure the frame and the joists.

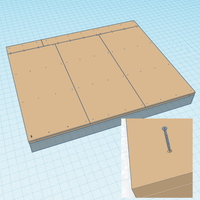

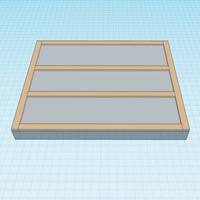

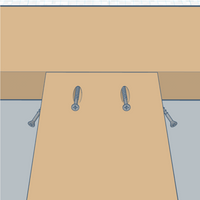

Once the coating is dry, place the frame pieces and the joists back onto the shed floor. All joists should be spaced 450mm apart. Make sure the coated side is facing down. This will stop moisture in the concrete slab from entering the timber.

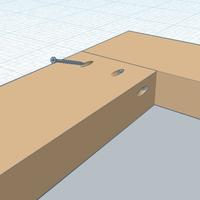

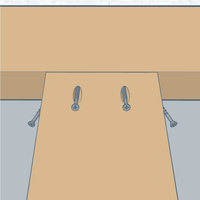

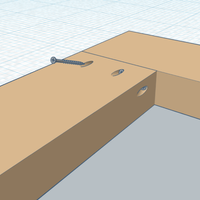

Use a drill driver to pre-drill and countersink 3mm holes in the top and sides of the frame pieces and the joists at their ends.

Now use 65mm timber screws to attach the frame pieces together. Secure the joists to the frame.

Step 6

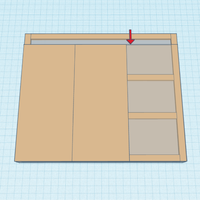

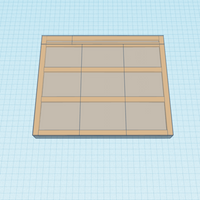

Lay the flooring.

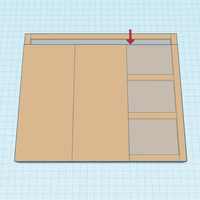

Lay the flooring sheets over the joists.

If the sheets are too long for your shed, use a circular saw to trim them to the appropriate size before laying them.

If the sheets are too short to span the entire floor, you'll need another sheet to fill the gap. Measure the gap and cut a strip of flooring to fit accordingly.

As you lay each sheet, place a scrap piece of timber against it and gently tap it with a hammer to join them together.

Secure the sheets to the joists and frame using 45mm timber screws, ensuring you fix them around the perimeter frame and across the joists.

Optionally, you can leave the sheeting bare, or for enhanced water resistance, apply a polyurethane coating by painting it onto the surface.

To enhance your flooring's finish, you can also install a hybrid-vinyl flooring over the particleboard if needed.

You have now successfully installed a raised floor in your shed.

Materials

- Structural flooring, like 1800 x 800mm 19mm Flooring Particleboard Yellow Tongue Structural

- Seven 90 x 35mm H3-treated Pine lengths (for a 2 x 2m shed)

- 65mm x 10g timber screws

- 45mm x 10g timber screws

- Bitumen waterproofing membrane

- Polyurethane coating (optional)

- Hybrid-vinyl flooring (optional).

Tools

- Hammer

- Tape measure

- Drill driver

- Circular saw

- 3mm drill bit

- Countersink drill bit

- Two disposable paint rollers

- Personal protective equipment, like gloves and safety glasses.

Images

- Tags:

- Garage and Shed

You must be a registered Workshop community member to comment. Please join Workshop or sign in to join in the discussion.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.