- Bunnings Workshop

- >

- How To

- >

- How to build a deck

How to build a deck

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Intermediate

Create the perfect entertainment space with this simple deck. Its floating design allows for a quick and easy installation in any backyard.

Video Tutorial

Steps

Step 1

Mark out an appropriate location for your deck. It is best if the area is relatively flat and preferably with adequate drainage. Areas which become sodden with water regularly and have poor drainage are not suitable for a low-lying deck.

Remove any rocks and debris and then spread sand with a rake to level the area as well as possible. If the site has a slope, it might be necessary to cut into the soil and reduce the gradient.

Dampen the soil with water before compacting the sand with a hand tamper. Go over the area a couple of times until the ground becomes noticeably more solid. You can tell the site is compacted sufficiently when the sound from your tamper turns from a dull thud into a higher-pitched ring.

For larger areas, mechanically compactors should be considered. They are readily available for hire.

Step 2

Once your area is flat and compacted, lay down weed matting and cover with a 50mm layer of drainage gravel. The drainage gravel will ensure that water does not pool directly under the decking timber and can freely drain away.

Step 3

To construct your outer frame, take four lengths of your 90mm x 45mm framing timber and join them at their corners with two 125mm galvanised bugle-head screws in each corner. Pre-drill the screw holes with a 4mm drill to prevent splitting.

Once you have built your deck's frame, you can set out your pavers, providing the pedestal feet with a solid base. The structure will need to be supported no more than every metre. At this stage, the bare frame will only need a pedestal foot for support every metre or so, but we will be adding more pedestal feet later to support the joists. Use the adjustment screws on the feet to level the frame.

Step 4

Cut several 300mm lengths of your framing timber which will be used as spacers between the frame and the first joist. This double-joist allows our picture frame boards to be fixed into the spacers.

Screw your spacers into the inside of your frame approximately 450mm apart. Place your first joist up against the spacers and screw both its ends into the frame. Next fix an additional screw into each spacer. This ties the frame to the spacer and the spacer to the first joist.

Step 5

Measure the distance between the double-joists and divide that by 450mm. These will be the locations for your joists. Once the joist locations are established, you can lay out your additional pavers and pedestal feet to support the joists. The joists need to be supported every metre.

Install your joists across the frame at 450mm centres. Use two 125mm bugle screws at each joint through your frame and into both ends of the joists.

Adjust the pedestal feet to meet the bottom of the joists and provide support.

Step 6

To create your fascia boards, take four lengths of your decking timber and cut them 100mm longer than the sides of your frame. The additional length allows you to make 45-degree cuts at their ends. Three of these boards can then be attached around the face of the frame with stainless steel self-drilling decking screws. If you are not using self-drilling decking screws, you will first need to pre-drill and countersink your holes. Leave one fascia board off at this time.

Step 7

Install a framing board on the opposite side of the deck to the missing fascia board. This board will run perpendicular to the others and finishes their ends neatly. The ends of your decking boards will butt up against this board. This board is spaced 5mm away from the fascia board with packers and is screwed into the frame and spacers installed earlier. As you butt your decking board ends up against this board, keep a 5mm gap which is once again established with the 5mm plastic packers.

Step 8

Starting at the first joist, screw your decking boards down at each joist location with two decking screws. Space these screws 15mm in from the edge of the decking board.

As you lay your boards, it is important to maintain a 5mm spacing with the 5mm plastic packers and check periodically that you are tracking evenly across the deck. You can check by measuring from your first board to the last board you have laid. Measure on both ends of the board and ensure the distances are the same. If your boards are tracking un-evenly and are not parallel to the first board, you can adjust your gaps to bring them back true. This is done by instead of having a 5mm gap, make it + or – 1mm. Slowly over the following few boards, continue adjusting until the boards are parallel.

It is important that you deal with this issue periodically across the deck. Otherwise, when you reach the last board, you will find it is entirely out of parallel to the fascia board. You will then need to backtrack, pulling up boards to correct the issue.

Step 9

Once the decking boards have been fixed into position, you can use a string line to mark their ends ready to trim. Ensure there is enough room between the outside of the frame and ends of the boards to accommodate your framing board. Take your circular saw and trim the boards to length.

Install your last framing board, which runs perpendicular to your decking boards. You can then fix the final fascia board onto the face of the frame to finish the deck's construction.

Step 10

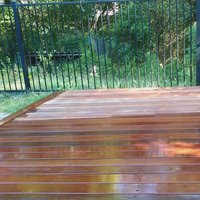

To avoid the six to eight-week weathering process on new Merbau timber, use Cabot's New Timber Prep solution to strip out tannins. Once the deck is dry, apply a coat of decking oil with a lambswool applicator. Wait the prescribed amount of time according to instructions before applying your second coat. In most cases, if you apply the first coat in the morning, you will be able to apply your second on the same day.

If rain is forecast, it is best to cover the deck with a tarp to avoid any discolouration.

Once the oil has dried, you can enjoy your new entertainment and relaxation space.

Materials

- Merbau decking

- 90mm x 45mm outdoor H3 framing Pine timber

- Adjustable pedestal feet

- Drainage gravel

- Sand

- 300mm x 300mm x40mm cement pavers

- Stainless steel self-drilling decking screws 12G x 65mm

- 125mm galvanised bugle-head screws

- Decking oil

- Cabot’s new timber prep solution.

Tools

- Cordless drill driver

- Circular saw

- Deck scrubbing brush

- Oil application mop

- Level

- String line

- Hand tamper

- Rake

- 5mm plastic packers

- Tape measure

- 4mm drill-bit.

Images

You must be a registered Workshop community member to comment. Please join Workshop or sign in to join in the discussion.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.