The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Featured Projects

- >

- Low-level deck with custom timber deckin...

Low-level deck with custom timber decking tiles

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

A comprehensive balcony makeover including new timber decking, furniture, screening for the air conditioning unit, and artificial grass.

- The project

- Planning and design

- Air conditioner cover and barbecue stand

- Staining timber framed windows

- Painting the steel railing and screening panels

- Bar table with matching stools

- Custom timber decking tiles

- Artificial grass tiles

- Before and after

- How to build a low-level deck

- More inspiration for your outdoor areas

The project

I recently completed a project I'd been planning for years and I'm excited to share the finished result with you all. Ever since purchasing my apartment, I've dreamt of transforming my apartment balcony from the dirty, overgrown space I started with, to an inviting outdoor retreat that I'm motivated to use every day. I had countless ideas to achieve this, ranging from a clever BBQ stand to hide the air con, to crazy ideas to try to construct a low-level deck. At one stage I even considered trying to raise the height of the balcony railing to accommodate this.

After years of planning and indecision (and some wise words from the Workshop community - special shoutout to MitchellMc) I'm thrilled with the results.

I split the project into six parts.

Planning and design

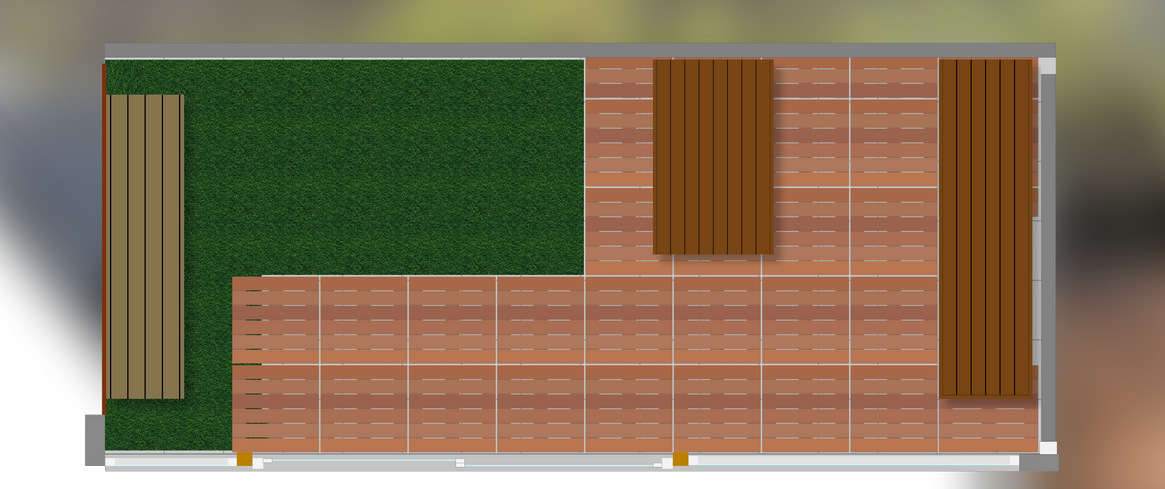

After taking measurements of the space, I got to work planning and designing the project in the web-based design tool, Figma. I made countless iterations on this layout. This is the final design.

Air conditioner cover and barbecue stand

I had already finished the first part of the whole outdoor project with my Dad. The air con/BBQ stand project was done using Merbau decking and I shared a detailed write-up about it in 2020.

This did an excellent job of hiding the unsightly air conditioner.

Staining timber framed windows

The timber uprights around my windows were looking a little tired. I sanded them back to bare timber.

Then I stained them with Cabot's Maple Exterior Varnish Stain.

Painting the steel railing and screening panels

The balcony railing was also in need of some TLC.

After a good clean, I brought the white screening panels back to life with a fresh coat of paint. Then I sanded the steel railing and painted it with White Knight Rust Guard Epoxy Enamel Aluminium.

Bar table with matching stools

A special part of this project for me was building a bar table in Dad's signature style, using recycled timber he had on hand. I also put together a pair of stools to match, taking inspiration from some examples I'd seen online. I stained these with the same can of maple varnish I'd used on the timber uprights.

They came together looking like this.

Custom timber decking tiles

Years after trying to build a 'real' deck on my balcony, I came around to the idea of timber decking tiles. The key restriction was the deck could be no higher than 55mm as my balcony railing is 1055mm high and must maintain at least 1000mm clearance above the deck.

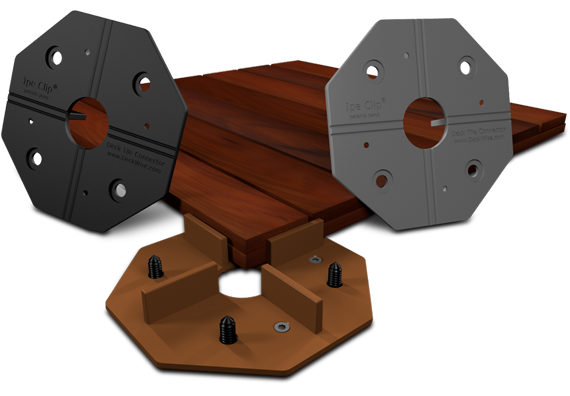

I considered composite timber decking tiles, but the look wasn't quite right. Through my research, I came across DeckWise in Florida, USA. DeckWise's Deck Tile Connector system was perfect for my situation. These connectors are low enough to ensure the deck is low-level, while still lifting each tile high enough off the tiled surface to ensure adequate drainage underneath.

I couldn't find these stocked anywhere in Australia. I contacted DeckWise directly, who shipped the connectors to me.

Then I got to work constructing my own timber decking tiles. Running low on recycled timber, I decided to use the 70mm Specrite Fence Pickets for this project. Based on 70mm timber, six boards per tile and with 5mm board spacing, I decided to make my tiles 445mm x 445mm.

The fence pickets come pre-oiled, but I sanded them down to bare timber before making my cuts. That allowed me to later oil them myself to accurately mimic a timber deck. I also knew all the cut ends would need oil anyway, which wouldn't usually be an issue for someone using these as fence pickets. This step might have been unnecessary - I could have layered my decking oil on top of the initial stain and dealt with the cut ends as part of the second coat. I'm interested to hear the community's thoughts on how this might have turned out.

I needed 269 individual pieces for this project - which meant almost a full day of cuts. With the cuts completed, I gave the ends a quick sand and then began oiling them by hand with Cabot's Merbau Aquadeck Exterior Decking Oil. This was an incredibly long process but I wanted to ensure each piece, including those underneath the tiles which will be difficult to re-oil in the future, was protected from the elements.

Finally, I was ready to assemble the tiles. The decking boards are 19mm thick (two boards deep), so I used 30mm countersunk exterior timber screws to assemble them (36 screws per tile). Each tile took about twenty minutes to assemble, so this was another marathon process.

Two products made my life much easier here. One was the Macsim Countersinking tool - I drilled almost 1000 countersunk holes without breaking a single drill bit. The other was the Icon Plastics Deck Spacer.

Now the tiles were ready for the next step.

After a solid three days building the tiles, I was very nervous about the installation. Using one of the connectors as a template, as DeckWise recommends, I drilled 9.5mm holes 20mm deep in each corner. A makeshift drill stop made this job very straightforward. I then put my connectors in place and began slotting the tiles together. Incredibly, these slotted into place without a single issue - I'm beyond impressed with these connectors.

Once assembled, I gave my new 'deck' two more coats of Cabot's Aquadeck. The ends of each tile within the decks have only had one proper coat of oil, plus the drips from the final two coats. Is it worth lifting up the edge of each tile to give these a touch-up?

Artificial grass tiles

With the deck completed, the space was ready for the sixth and final part of my project - the artificial grass. It was easy to install, and it looks and feels great. I used a jigsaw the cut the tiles to size along the railing.

It was a marathon project - but absolutely worth the effort, and I'm thrilled with the final result.

Before and after

How to build a low-level deck

Experienced Workshop community member Adam_W has shared a comprehensive guide how to build a low-level deck.

More inspiration for your outdoor areas

Creative member homeinmelbourne has detailed how they built screening for an air conditioning unit.

You can get more inspiration from our Top 10 most popular deck projects on Workshop.

If you need a hand with your own project, hit the Start a discussion button and we would be more than happy to help.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects