The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Featured Projects

- >

- Custom Red Oak tool cabinet on wheels

Custom Red Oak tool cabinet on wheels

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

This timber tool cabinet can be separated into two parts for easy transport.

The project

I wanted to build a tool cabinet that was simple and mobile and could be split into two parts if I ever moved house.

I decided to use veneered Red Oak ply from Bunnings as well as Birch ply, with solid Red Oak for the doors. I really like the solid Red Oak project panels from Bunnings – they save me having to mill the boards myself.

All the edge banding was done using an iron-on White Oak veneer. All the joinery is tongue and groove or dowels.

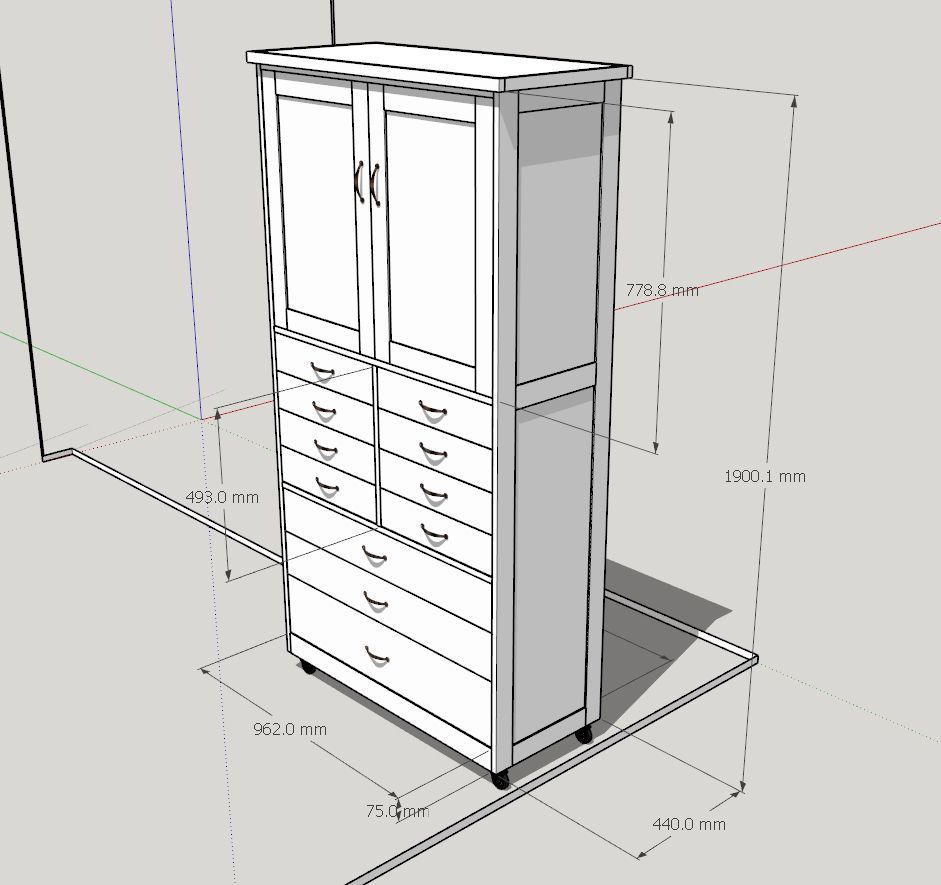

The plan originally started out as a drawing, then I transferred the idea to SketchUp's 3D rendering program.

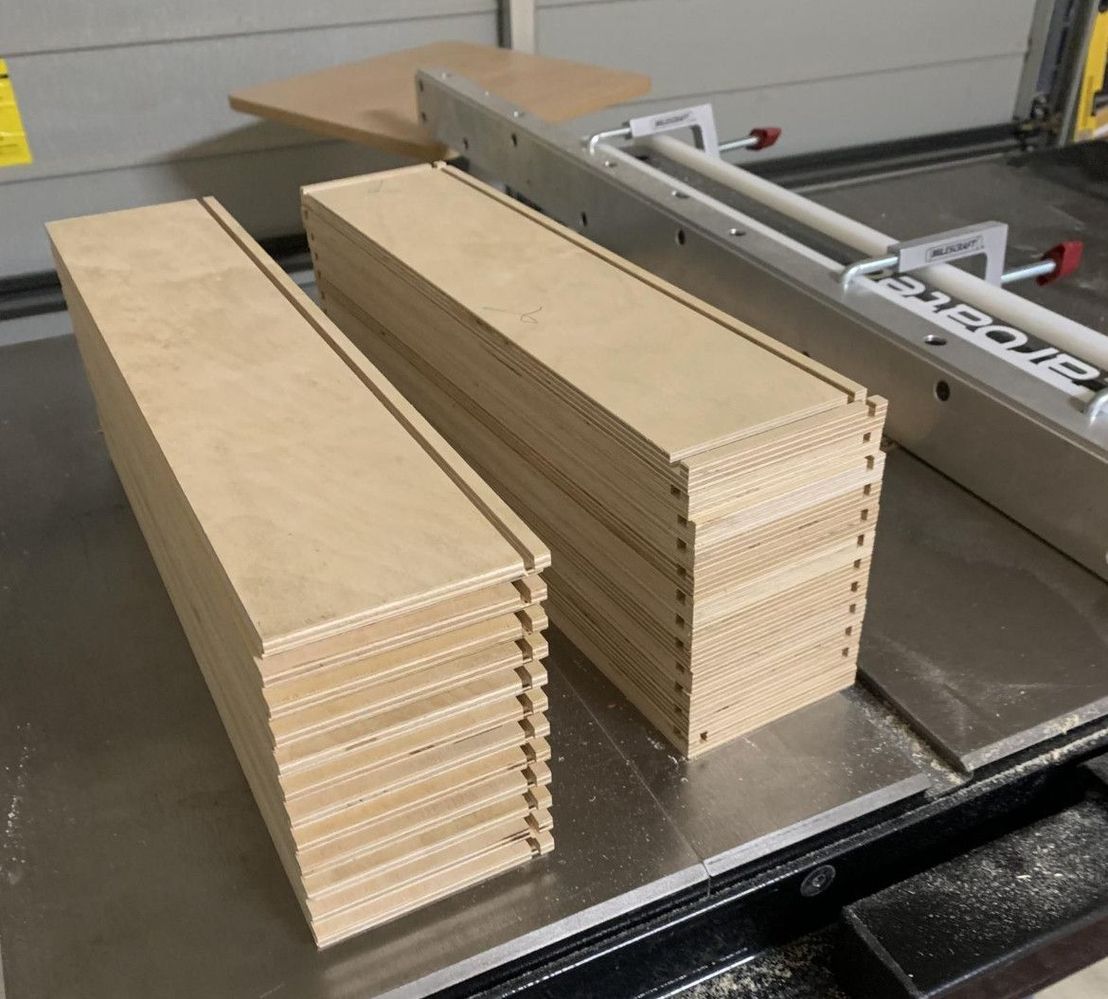

Some of the plywood cut to size.

The base complete. I later glued a strip of Red Oak veneer to the front to hide the screws.

The back panel and mid support glue-up, using dowel joinery.

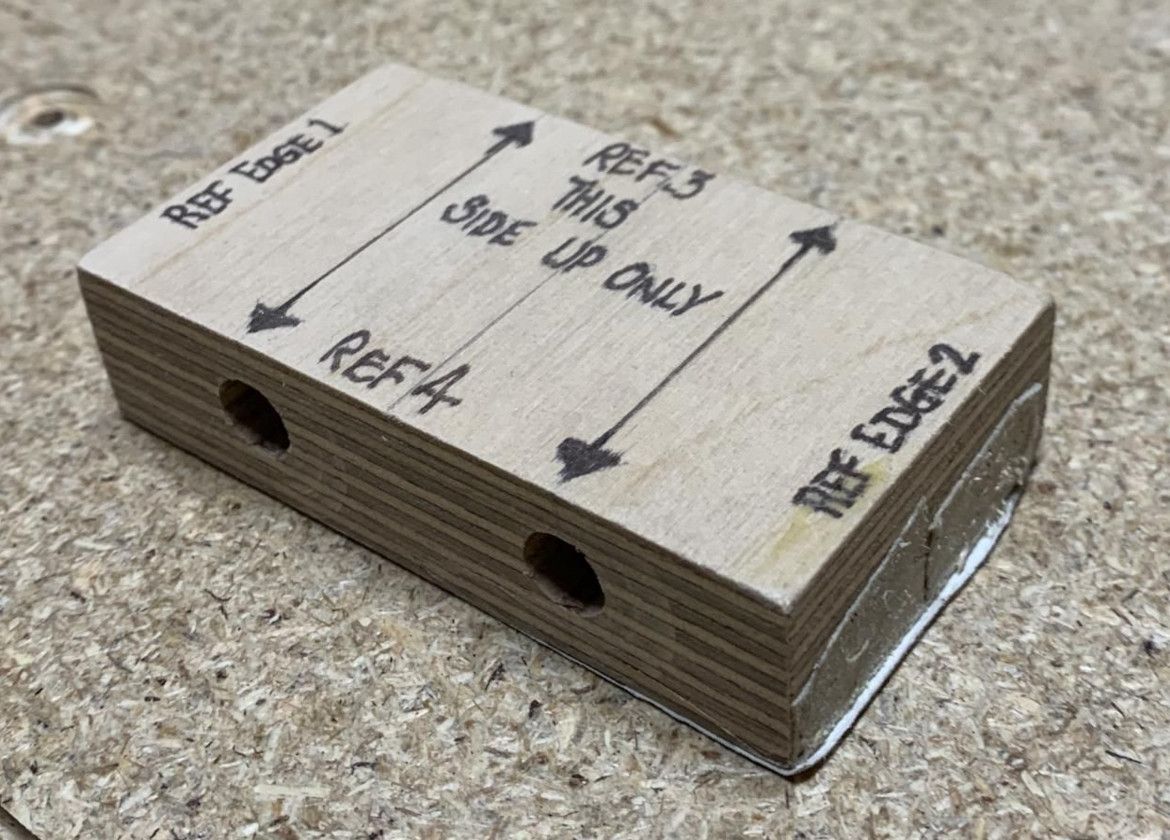

The most accurate doweling jig is one you make yourself – I've tried many and none of them were accurate enough for me. Here's mine.

Veneered Red Oak glue-up to hide the front base screws.

After assembling the carcass I started gluing the rails and stiles to the sides, which hid all the screws. I left a few millimetres around the edges so I could flush-trim them using the router.

Carcass complete and checked for squareness!

The top and wheels added.

Close-up of some of the veneer.

I made the drawers using tongue-and-groove joins. Everything went together pretty well, but at this point I started to get tennis elbow – something I've never suffered with until now!

I was going to make my own runners but opted to buy some cheap ones for the small drawers and some soft-closers for the bottoms.

Attaching the veneered plywood fronts.

Door assembly using solid Red Oak for the stiles and rails. I've never worked with Red Oak before and

suddenly realised during cutting the stuff that it has a very distinct smell.

Shellac time! Three coats of the hard stuff. It dries quick and you can cut it back to whatever sheen you want. You just can't beat traditional finishes.

I cut the sheen back using 0000 steel wool to create a nice, even satin finish that still shows the grain – just how I wanted it. I also added a little dark Oak tint to the first coat of shellac to make the grain pop a bit more.

From start to finish I think it took about three months on and off. For small garages and if you rent it's a good idea to keep everything mobile by putting wheels on everything.

More project inspiration

Experienced Workshop member Joe upcycled this attractive and functional workbench using wheels and a larger frame to offer more workspace and portability.

Workshop member Kel made this striking custom storage cabinet using pieces of scrap timber.

There are also plenty of great ideas in our collections of Tool storage solutions and 8 inspiring cabinet projects.

Let us know if you need a hand with your own project – we're here to help.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects